Une histoire qui dure...

DEPUIS PLUS DE 85 ANS

1927

C’est l’année où tout commence. De retour de service militaire Juste Lucain Husseau et René Moynaton s’associent pour acquérir une parcelle de terrain à La Plainelière de Courlay dans les Deux-Sèvres. Sur cette parcelle, ils construisent un premier bâtiment (qui existe toujours) pour y loger des métiers à tisser. L’activité démarre alors avec la réalisation de matières premières simples, toiles et sergés de coton.

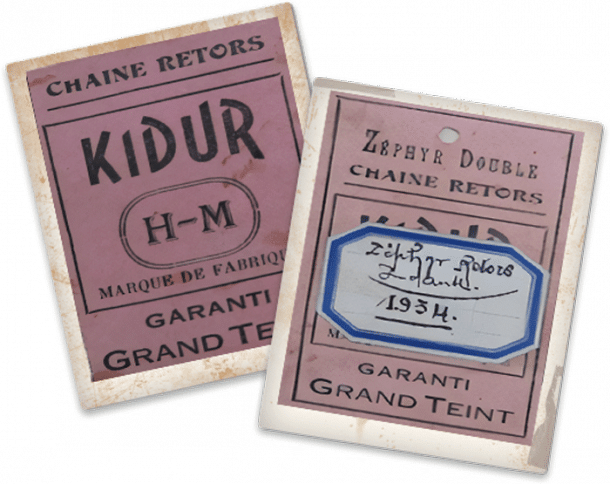

1934

Juste & René se sont progressivement fait connaître pour la qualité de leurs fabrications. Des tissus qui durent, des tissus qui résistent à l’usure et dont la couleur tient au lavage. Ces matières permettaient de confectionner des vêtements made in France solides, de très bonne qualité qui duraient très longtemps à l’usage (condition essentielle en ce temps là) Progressivement “QUI DURE” se transforme en KIDUR. Et c’est au détour d’une couverture de la collection de 1934 qu’on voit pour la première fois apparaître la marque KIDUR.

1935

La marque KIDUR est déposée le 28 Octobre 1935 avec son logo d’origine. Le tissu “KIDUR”, résiste à l’usure. Ainsi démarre officiellement l’aventure de Kidur, qui ne cessera d’être fabriqué à la Plainelière de Courlay.

1935

1945

1955

2018

1939

L’activité de tissage KIDUR, forte de 20 métiers à tisser est ralentie par l’arrivée de la guerre et les difficultés d’alimentation en fils de coton. Pendant l’occupation, Juste Husseau et l’un de ses amis, Jacques Roy recueillent et cachent à la Plainelière des réfractaires au travail obligatoire en Allemagne. En signe de résistance, ils accueillent également des officiers et des aviateurs Anglais et assurent leur évasion hors de France. C’est à la fin des hostilités, pressentant la pénurie de tissus liée au manque de production des dernières années, que les deux fondateurs décident de construire un nouvel atelier, où 48 métiers à tisser seront remis en état par ces militaires patriotes et alliés.

1945

1945, fin des hostilités. Juste & René développent l’entreprise de vêtement qui dure. L’atelier de confection est agrandi et doté d’une école de formation professionnelle. Dès seize ans, les jeunes garçons et les jeunes filles du canton vont travailler chez Kidur avec la certitude d’y apprendre un métier, tisseur ou couturière. Cette volonté de maintenir et transmettre les savoir-faire ne nous quittera jamais.

1960/70

L'âge d'or à la Plainelière

C’est l’âge d’or de la manufacture Kidur. Près de 400 personnes tissent, coupent et confectionnent au quotidien toutes les pièces du vestiaire masculin fonctionnel. Avec pour seules obsessions : la qualité, la durabilité. A cette époque Kidur est vendu en France grâce à une escouade de vendeurs, bien connus pour leurs camions KIDUR. Les représentants Kidur parcourent la campagne et proposent aux boutiques, ou directement aux consommateurs les produits de la manufacture. A l’époque, Kidur fabriquait pantalons, côtes, chemises, surchemises, vestes et salopettes. Ces vêtements constituaient le vestiaire essentiel du travailleur. Des pièces de cette époque se retrouvent aujourd’hui dans les boutiques Vintage du monde entier.

1988

La manufacture rencontre des difficultés, les vêtements Made in France sont boudés au profit des productions importées. Des cadres ardents défenseurs du Made in France reprennent le flambeau et décident d’employer les savoir-faire de la manufacture aux profits d’autres activités comme la fabrication pour les marques de Luxe.

Kidur continue toujours d’être fabriqué à Courlay, mais dans une proportion réduite.

2018

La manufacture décide de relancer la machine et de mettre en avant son petit bout de patrimoine.

Notre équipe qui dure a pensé et mis au point une nouvelle collection inspirée de notre précieux patrimoine. Celle-ci regroupe modèles d’époque Kidur, archives, récits et souvenirs de nos anciennes couturières,

Kidur est alors proposé au plus grand nombre, via une collection de vêtements faits en France, à Courlay, dans l’atelier d’origine.

2021

94 ans après, le site industriel berceau de la marque est toujours en activité. La société compte aujourd’hui 80 membres dont la moitié sont des artisans couturiers. Kidur est la volonté d’une confection française de lier savoir-faire traditionnel, patrimoine historique avec une organisation moderne. Autour de ces valeurs d’origine, la manufacture s’emploie chaque jour à réaliser et distribuer une gamme de vêtements bien conçus et de haute qualité. Kidur propose plus qu’un simple vestiaire, il s’agit d’un état d’esprit, la volonté de prendre le temps de confectionner en France des vêtements qui durent.